Page 149 - CITS - ED - Mechanical

P. 149

ENGINEERING DRAWING - CITS

Rivets

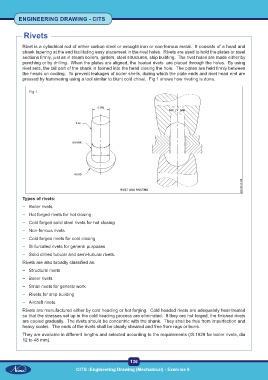

Rivet is a cylindrical rod of either carbon steel or wrought iron or non-ferrous metal. It consists of a head and

shank tapering at the end facilitating easy placement in the rivet holes. Rivets are used to hold the plates or steel

sections firmly, just as in steam boilers, girders, steel structures, ship building. The rivet holes are made either by

punching or by drilling. When the plates are aligned, the heated rivets are placed through the holes. By using

rivet sets, the tail part of the shank is formed into the head closing the hole. The plates are held firmly between

the heads on cooling. To prevent leakages of boiler shells, during which the plate ends and rivet head end are

pressed by hammering using a tool similar to blunt cold chisel. Fig 1 shows how riveting is done.

Fig 1

Types of rivets:

– Boiler rivets

– Hot forged rivets for hot closing

– Cold forged solid steel rivets for hot closing

– Non-ferrous rivets

– Cold forged rivets for cold closing

– Bi-furcated rivets for general purposes

– Solid drilled tubular and semi-tubular rivets.

Rivets are also broadly classified as:

– Structural rivets

– Boiler rivets

– Small rivets for general work

– Rivets for ship building

– Aircraft rivets.

Rivets are manufactured either by cold heading or hot forging. Cold headed rivets are adequately heat-treated

so that the stresses set up in the cold heading process are eliminated. If they are hot forged, the finished rivets

are cooled gradually. The rivets should be concentric with the shank. They shall be free from imperfection and

heavy scales. The ends of the rivets shall be clearly sheared and free from rags or burrs.

They are available in different lengths and selected according to the requirements (IS:1928 for boiler rivets, dia

12 to 48 mm).

136

CITS :Engineering Drawing (Mechanical) - Exercise 8