Page 151 - CITS - ED - Mechanical

P. 151

ENGINEERING DRAWING - CITS

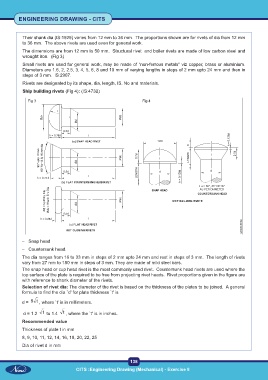

Their shank dia (IS:1929) varies from 12 mm to 36 mm. The proportions shown are for rivets of dia from 12 mm

to 36 mm. The above rivets are used even for general work.

The dimensions are from 12 mm to 50 mm. Structural rivet and boiler rivets are made of low carbon steel and

wrought iron. (Fig 3)

Small rivets are used for general work, may be made of "non-ferrous metals" viz copper, brass or aluminium.

Diameters are 1.6, 2, 2.5, 3, 4, 5, 6, 8 and 10 mm of varying lengths in steps of 2 mm upto 24 mm and then in

steps of 3 mm. IS:2907.

Rivets are designated by its shape, dia, length, IS. No and materials.

Ship building rivets (Fig 4): (IS:4732)

Fig 3 Fig 4

– Snap head

– Countersunk head.

The dia ranges from 16 to 33 mm in steps of 2 mm upto 24 mm and rest in steps of 3 mm. The length of rivets

vary from 27 mm to 180 mm in steps of 3 mm. They are made of mild steel bars.

The snap head or cup head rivet is the most commonly used rivet. Countersunk head rivets are used where the

top surface of the plate is required to be free from projecting rivet heads. Rivet proportions given in the figure are

with reference to shank diameter of the rivets.

Selection of rivet dia: The diameter of the rivet is based on the thickness of the plates to be joined. A general

formula to find the dia `d' for plate thickness `t' is

d = , where `t' is in millimeters.

d = 1.2 to 1.4 , where the `t' is in inches.

Recommended value

Thickness of plate t in mm

8, 9, 10, 11, 12, 14, 16, 18, 20, 22, 25

Dia of rivet d in mm

138

CITS :Engineering Drawing (Mechanical) - Exercise 8