Page 212 - CITS - ED - Mechanical

P. 212

ENGINEERING DRAWING - CITS

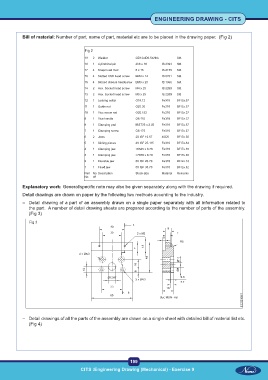

Bill of material: Number of part, name of part, material etc are to be placed in the drawing paper. (Fig 2)

Fig 2

19 2 Washer OD12xID6.5x2thk Std

18 1 Cylindrical pin 4h8 x 16 IS:2393 Std

17 4 Snap head rivet 6 x 15 IS:2155 Std

16 4 Slotted CSK head screw BM4 x 14 IS:6761 Std

15 4 Slotted cheese headscrew BM3 x 25 IS:1366 Std

14 2 Hex. Socket head screw M4 x 25 IS:2269 Std

13 2 Hex. Socket head screw M5 x 25 IS:2269 Std

12 1 Locking coltar O18.12 Fe310 BF Ex.37

11 1 Guide nut O25.30 Fe310 BF Ex.37

10 1 Vice screw rod O20.152 Fe310 BF Ex.37

9 1 Vice handle O8.115 Fe310 BF Ex.37

8 1 Clamping pad ISST35 x 2.35 Fe310 BF Ex.37

7 1 Clamping screw O8.175 Fe310 BF Ex.37

6 2 Jaws 20 ISF 10.67 40C8 BF Ex.36

5 1 Sliding pieces 40 ISF 25.115 Fe310 BF Ex.34

4 1 Clamping jaw <6545 x 8.70 Fe310 BF Ex.35

3 1 Clamping jaw <7070 x 8.70 Fe310 BF Ex.35

2 1 Movable jaw 50 ISF 20.70 Fe310 BF Ex.33

1 1 Fixed jaw 50 ISF 30.70 Fe310 BF Ex.32

Part No Description Stock size Material Remarks

No. off

Explanatory work: General/specific note may also be given separately along with the drawing if required.

Detail drawings are drawn on paper by the following two methods according to the industry.

– Detail drawing of a part of an assembly drawn on a single paper separately with all information related to

the part. A number of detail drawing sheets are prepared according to the number of parts of the assembly.

(Fig 3)

Fig 3

– Detail drawings of all the parts of the assembly are drawn on a single sheet with detailed bill of material list etc.

(Fig 4)

199

CITS :Engineering Drawing (Mechanical) - Exercise 9 CITS :Engineering Drawing (Mechanical) - Exercise 9