Page 215 - CITS - ED - Mechanical

P. 215

ENGINEERING DRAWING - CITS

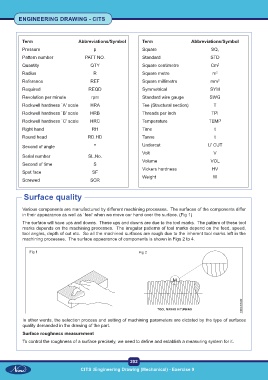

Term Abbreviations/Symbol Term Abbreviations/Symbol

Pressure p Square SQ,

Pattern number PATT NO. Standard STD

Quantity QTY Square centimetre Cm 2

Radius R Square metre m 2

Reference REF Square millimetre mm 2

Required REQD Symmetrical SYM

Revolution per minute rpm Standard wire gauge SWG

Rockwell hardness `A' scale HRA Tee (Structural section) T

Rockwell hardness `B' scale HRB Threads per inch TPI

Rockwell hardness `C' scale HRC Temperature TEMP

Right hand RH Time t

Round head RD.HD Tanne t

Second of angle " Undercut U' CUT

Volt V

Serial number SL.No.

Volume VOL

Second of time S

Vickers hardness HV

Spot face SF

Weight W

Screwed SCR

Surface quality

Various components are manufactured by different machining processes. The surfaces of the components differ

in their appearance as well as `feel' when we move our hand over the surface. (Fig 1)

The surface will have ups and downs. These ups and downs are due to the tool marks. The pattern of these tool

marks depends on the machining processes. The irregular patterns of tool marks depend on the feed, speed,

tool angles, depth of cut etc. So all the machined surfaces are rough due to the inherent tool marks left in the

machining processes. The surface appearance of components is shown in Figs 2 to 4.

Fig 1 Fig 2

In other words, the selection process and setting of machining parameters are dictated by the type of surfaces

quality demanded in the drawing of the part.

Surface roughness measurement

To control the roughness of a surface precisely, we need to define and establish a measuring system for it.

202

CITS :Engineering Drawing (Mechanical) - Exercise 9