Page 263 - Electrician - TT (Volume 1)

P. 263

ELECTRICIAN - CITS

For example

1 The oil may come in contact with the air, there by presence of moisture and dust in the oil. The presence of

moisture is harmful and affects the electrical characteristics of oil and will accelerate deterioration of insulating

materials.

2 Sediment and precipitable sludge may be formed on the winding and core surfaces. It will reduce the cooling

rate and hence it may lead to deterioration of the insulating materials.

3 The presence of certain solid iron, copper and dissolved metallic compounds will increase the acidity. In

such cases, the resistivity decreases, and electrical strength also decreases, and it is also the causes for

deterioration of transformer oil.

Testing of transformer oil: For reliable use and maintenance of oil cooled transformer, the transformer oil

shall be tested before initial filling of the oil as well as during service of the transformers. As per the test result it

may be required to filter the transformer oil or in some cases, new oil may be recommended for safe and better

maintenance of oil cooled transformers.

The following tests are conducted periodically to decide the performance of the transformer oil.

1 Field test of insulation oil

2 Crackle test of insulating oil

3 Dielectric test of insulating oil

4 Acidity test.

1 Field test of insulating oil

A drop of transformer oil, when placed slowly from a pipette on the still surface of a distilled water contained in

heater should retain its shape when the oil is new.

In the case of used cyclo-octane oils (or) paraffin oils (even though unused) the drop usually flattened. If this

flattened drop occupies an area of diameter less than 15 to 18 mm, the oil may be used. Otherwise, it has to be

reconditioned. Oils with the longer spreads are unsuitable.

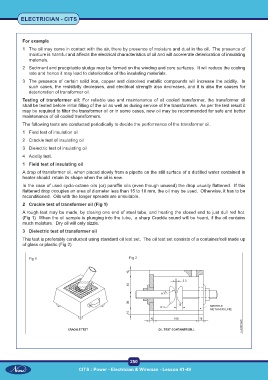

2 Crackle test of transformer oil (Fig 1)

A rough test may be made, by closing one end of steel tube, and heating the closed end to just dull red hot.

(Fig 1) When the oil sample is plunging into the tube, a sharp Crackle sound will be heard, if the oil contains

much moisture. Dry oil will only sizzle.

3 Dielectric test of transformer oil

This test is preferably conducted using standard oil test set. The oil test set consists of a container/cell made up

of glass or plastic.(Fig 2)

Fig 1 Fig 2

250

CITS : Power - Electrician & Wireman - Lesson 41-49