Page 264 - Electrician - TT (Volume 1)

P. 264

ELECTRICIAN - CITS

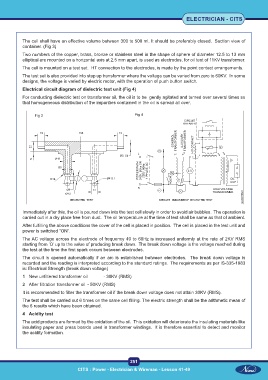

The cell shall have an effective volume between 300 to 500 ml. It should be preferably closed. Section view of

container. (Fig 3)

Two numbers of the copper, brass, bronze or stainless steel in the shape of sphere of diameter 12.5 to 13 mm

elliptical are mounted on a horizontal axis at 2.5 mm apart, is used as electrodes, for oil test of 11KV transformer.

The cell is mounted on a test set. HT connection to the electrodes, is made by the point contact arrangements.

The test set is also provided into step up transformer where the voltage can be varied from zero to 60KV. In some

designs, the voltage is varied by electric motor, with the operation of push button switch.

Electrical circuit diagram of dielectric test unit (Fig 4)

For conducting dielectric test on transformer oil, the oil is to be gently agitated and turned over several times so

that homogeneous distribution of the impurities contained in the oil is spread all over.

Fig 3 Fig 4

Immediately after this, the oil is poured down into the test cell slowly in order to avoid air bubbles. The operation is

carried out in a dry place free from dust. The oil temperature at the time of test shall be same as that of ambient.

After fulfilling the above conditions the cover of the cell is placed in position. The cell is placed in the test unit and

power is switched “ON”.

The AC voltage across the electrode of frequency 40 to 60Hz is increased uniformly at the rate of 2KV RMS

starting from ‘O’ up to the value of producing break down. The break down voltage is the voltage reached during

the test at the time the first spark occurs between electrodes.

The circuit is opened automatically if an arc is established between electrodes. The break down voltage is

recorded and the reading is interpreted according to the standard ratings. The requirements as per IS-335-1983

is: Electrical Strength (break down voltage)

1 New unfiltered transformer oil - 30KV (RMS)

2 After filtration transformer oil - 50KV (RMS)

It is recommended to filter the transformer oil if the break down voltage does not attain 30KV (RMS).

The test shall be carried out 6 times on the same cell filling. The electric strength shall be the arithmetic mean of

the 6 results which have been obtained.

4 Acidity test

The acid products are formed by the oxidation of the oil. This oxidation will deteriorate the insulating materials like

insulating paper and press boards used in transformer windings. It is therefore essential to detect and monitor

the acidity formation.

251

CITS : Power - Electrician & Wireman - Lesson 41-49 CITS : Power - Electrician & Wireman - Lesson 41-49