Page 53 - Electrician - TT (Volume 1)

P. 53

ELECTRICIAN - CITS

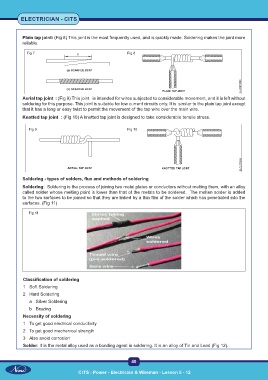

Plain tap joint: (Fig 8) This joint is the most frequently used, and is quickly made. Soldering makes the joint more

reliable.

Fig 7 Fig 8

Aerial tap joint : (Fig 9) This joint is intended for wires subjected to considerable movement, and it is left without

soldering for this purpose. This joint is suitable for low current circuits only. It is similar to the plain tap joint except

that it has a long or easy twist to permit the movement of the tap wire over the main wire.

Knotted tap joint : (Fig 10) A knotted tap joint is designed to take considerable tensile stress.

Fig 9 Fig 10

Soldering - types of solders, flux and methods of soldering

Soldering: Soldering is the process of joining two metal plates or conductors without melting them, with an alloy

called solder whose melting point is lower than that of the metals to be soldered. The molten solder is added

to the two surfaces to be joined so that they are linked by a thin film of the solder which has penetrated into the

surfaces. (Fig 11)

Fig 11

Classification of soldering

1 Soft Soldering

2 Hard Soldering

a Silver Soldering

b Brazing

Necessity of soldering

1 To get good electrical conductivity

2 To get good mechanical strength

3 Also avoid corrosion

Solder: It is the metal alloy used as a bonding agent in soldering. It is an alloy of Tin and Lead (Fig 12).

40

CITS : Power - Electrician & Wireman - Lesson 5 - 12