Page 54 - Electrician - TT (Volume 1)

P. 54

ELECTRICIAN - CITS

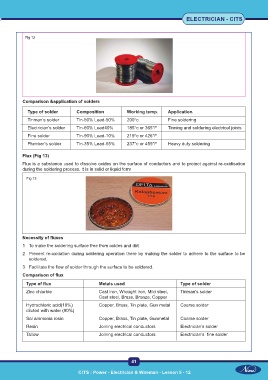

Fig 12

Comparison &application of solders

Type of solder Composition Working temp. Application

Tinman’s solder Tin-50% Lead-50% 200°c Fine soldering

Electrician’s solder Tin-60% Lead40% 185°c or 365°F Tinning and soldering electrical joints

Fine solder Tin-90% Lead-10% 219°c or 426°F

Plumber’s solder Tin-35% Lead-65% 237°c or 459°F Heavy duty soldering

Flux (Fig 13)

Flux is a substance used to dissolve oxides on the surface of conductors and to protect against re-oxidisation

during the soldering process. It is in solid or liquid form

Fig 13

Necessity of fluxes

1 To make the soldering surface free from oxides and dirt

2 Prevent re-oxidation during soldering operation there by making the solder to adhere to the surface to be

soldered.

3 Facilitate the flow of solder through the surface to be soldered.

Comparison of flux

Type of flux Metals used Type of solder

Zinc chloride Cast iron, Wrought iron, Mild steel, Tinman’s solder

Cast steel, Brass, Bronze, Copper

Hydrochloric acid(10%) Copper, Brass, Tin plate, Gun metal Coarse solder

diluted with water (90%)

Sal ammonia rosin Copper, Brass, Tin plate, Gunmetal Coarse solder

Resin Joining electrical conductors Electrician’s solder

Tallow Joining electrical conductors Electrician’s fine solder

41

CITS : Power - Electrician & Wireman - Lesson 5 - 12 CITS : Power - Electrician & Wireman - Lesson 5 - 12