Page 55 - Electrician - TT (Volume 1)

P. 55

ELECTRICIAN - CITS

Fluxes shown above 1, 2 and 3 are not recommended for electrical purpose. They are highly corrosive, hygroscopic

and the residues are electrically conductive.

Soldering techniques

1 Tinning the soldering iron.

2 Cleaning the parts to be soldered.

3 Applying the flux

4 Applying the solder.

Methods of soldering

1 Soldering with soldering iron

2 Soldering with soldering gun.

3 Soldering with flame.

4 Dip soldering.

5 Machine soldering.

6 Soldering with pot and ladle.

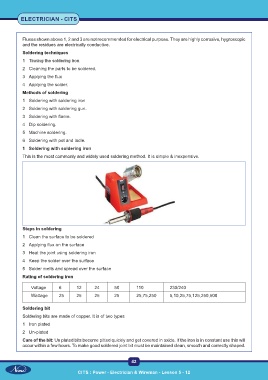

1 Soldering with soldering iron

This is the most commonly and widely used soldering method. It is simple & inexpensive.

Steps in soldering

1 Clean the surface to be soldered

2 Applying flux on the surface

3 Heat the joint using soldering iron

4 Keep the solder over the surface

5 Solder melts and spread over the surface

Rating of soldering iron

Voltage 6 12 24 50 110 230/240

Wattage 25 25 25 25 25,75,250 5,10,25,75,125,250,500

Soldering bit

Soldering bits are made of copper. It is of two types

1 Iron plated

2 Un-plated

Care of the bit: Un plated bits become pitted quickly and get covered in oxide. If the iron is in constant use this will

occur within a few hours. To make good soldered joint bit must be maintained clean, smooth and correctly shaped.

42

CITS : Power - Electrician & Wireman - Lesson 5 - 12