Page 213 - Electrician - TT (Volume 2)

P. 213

ELECTRICIAN - CITS

Changing of speed

The AC input supply provided, should match the voltage and frequency given on the nameplate. Improper

voltage may damage the drive.

Programming can be done through ‘MOD/RESET’ button in association with D and Ñ button and the drives

speed can be changed by using these buttons. The drive is started through ‘RUN’/STOP’ button.

The motor can be run at different speed by programming for the required speed.

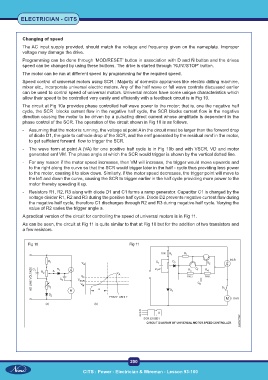

Speed control of universal motors using SCR : Majority of domestic appliances like electric drilling machine,

mixer etc., incorporate universal electric motors. Any of the half wave or full wave controls discussed earlier

can be used to control speed of universal motors. Universal motors have some unique characteristics which

allow their speed to be controlled very easily and efficiently with a feedback circuit is in Fig 10.

The circuit at Fig 10a provides phase controlled half wave power to the motor; that is, one the negative half

cycle, the SCR blocks current flow in the negative half cycle, the SCR blocks current flow in the negative

direction causing the motor to be driven by a pulsating direct current whose amplitude is dependent in the

phase control of the SCR. The operation of the circuit shown in Fig 10 is as follows.

- Assuming that the motor is running, the voltage at point A in the circuit must be larger than the forward drop

of diode D1, the gate to cathode drop of the SCR, and the emf generated by the residual mmf in the motor,

to get sufficient forward flow to trigger the SCR.

- The wave form at point A (VA) for one positive half cycle is in Fig 10b and with VSCR, VD and motor

generated emf VM. The phase angle at which the SCR would trigger is shown by the vertical dotted line.

- For any reason if the motor speed increases, then VM will increase, the trigger would move upwards and

to the right along the curve so that the SCR would trigger later in the half - cycle thus providing less power

to the motor, causing it to slow down. Similarly, if the motor speed decreases, the trigger point will move to

the left and down the curve, causing the SCR to trigger earlier in the half cycle providing more power to the

motor thereby speeding it up.

- Resistors R1, R2, R3 along with diode D1 and C1 forms a ramp generator. Capacitor C1 is charged by the

voltage divider R1, R2 and R3 during the positive half cycle. Diode D2 prevents negative current flow during

the negative half cycle, therefore C1 discharges through R2 and R3 during negative half cycle. Varying the

value of R2 varies the trigger angle a.

A practical version of the circuit for controlling the speed of universal motors is in Fig 11.

As can be seen, the circuit at Fig 11 is quite similar to that at Fig 10 but for the addition of two transistors and

a few resistors.

Fig 10 Fig 11

200

CITS : Power - Electrician & Wireman - Lesson 93-100