Page 210 - Electrician - TT (Volume 2)

P. 210

ELECTRICIAN - CITS

Parameter settings of DC drive

As discussed in previous chapter, the speed of DC motor is directly proportional to the armature voltage (Eb) and

inversely proportional to the field current(If) and also the armature current (Ia) is proportional motor torque.

In armature controlled DC drives, the drive unit provides a rated current and torque at any speed up to rated

speed.

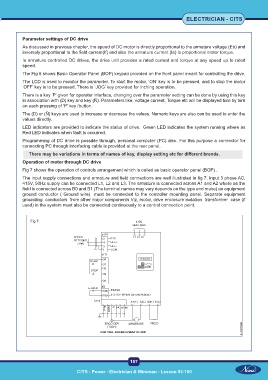

The Fig 6 shows Basic Operator Panel (BOP) keypad provided on the front panel meant for controlling the drive.

The LCD is used to monitor the parameter. To start the motor, ‘ON’ key is to be pressed, and to stop the motor

‘OFF’ key is to be pressed. There is ‘JOG’ key provided for inching operation.

There is a key ‘P’ given for operator interface, changing over the parameter setting can be done by using this key

in association with (D) key and key (Ñ). Parameters like, voltage current, Torque etc will be displayed turn by turn

on each pressing of ‘P’ key /button.

The (D) or (Ñ) keys are used to increase or decrease the values. Numeric keys are also can be used to enter the

values directly.

LED indicators are provided to indicate the status of drive. Green LED indicates the system running where as

Red LED indicates when fault is occurred.

Programming of DC drive is possible through, personal computer (PC) also. For this purpose a connector for

connecting PC through interfacing cable is provided at the rear panel.

There may be variations in terms of names of key, display setting etc for different brands.

Operation of motor through DC drive

Fig 7 shows the operation of controls arrangement which is called as basic operator panel (BOP) .

The input supply connections and armature and field connections are well illustrated in fig 7. Input 3 phase AC,

415V, 50Hz supply can be connected L1, L2 and L3. The armature is connected across A1 and A2 where as the

field is connected across B0 and B1 (The terminal names may vary depends on the type and make) an equipment

ground conductor ( Ground wire) must be connected to the controller mounting panel. Separate equipment

grounding conductors from other major components Viz, motor, drive enclosure isolation transformer case (if

used) in the system must also be connected continuously to a control connection point.

Fig 7

197

CITS : Power - Electrician & Wireman - Lesson 93-100 CITS : Power - Electrician & Wireman - Lesson 93-100