Page 358 - Electronic Mechanic - TP - Volume - 2

P. 358

ELECTRONICS MECHANIC - CITS

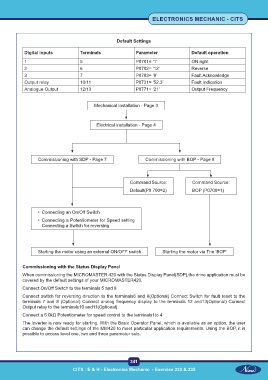

Default Settings

Digital inputs Terminals Parameter Default operation

1 5 P0701= ‘1’ ON right

2 6 P0702= ‘12’ Reverse

3 7 P0703= ‘9’ Fault Acknowledge

Output relay 10/11 P0731= ‘52.3’ Fault Indication

Analogue Output 12/13 P0771= ‘21’ Output Frequency

Mechanical Installation - Page 3

Electrical Installation - Page 4

Commissioning with SDP - Page 7 Commissioning with BOP - Page 8

Command Source: Command Source:

Default(P0 700=2) BOP (P0700=1)

• Connecting an On/Off Switch

• Connecting a Potentiometer for Speed setting

Connecting a Switch for reversing

Starting the motor using an external ON/OFF switch Starting the motor via The ‘BOP’

Commissioning with the Status Display Panel

When commissioning the MICROMASTER 420 with the Status Display Panel(SDP),the drive application must be

covered by the default settings of your MICROMASTER420.

Connect On/Off Switch to the terminals 5 and 8

Connect switch for reversing direction to the terminals6 and 8(Optional) Connect Switch for fault reset to the

terminals 7 and 8 (Optional) Connect analog frequency display to the terminals 12 and13(Optional) Connect

Output relay to the terminals10 and11(Optional)

Connect a 5.0kΩ Potentiometer for speed control to the terminals1to 4

The Inverter is now ready for starting. With the Basic Operator Panel, which is available as an option, the user

can change the default settings of the MM420 to meet particular application requirements. Using the BOP, it is

possible to access level one, two and three parameter sets.

341

CITS : E & H - Electronics Mechanic - Exercise 232 & 235