Page 239 - CITS - Fashion Design Technology - Trade Theory

P. 239

FASHION DESIGN & TECHNOLOGY - CITS

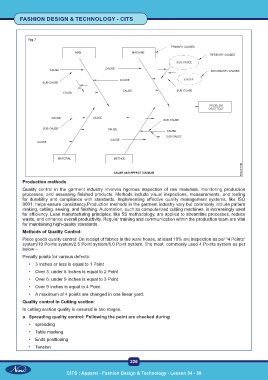

Fig 7

Production methods

Quality control in the garment industry involves rigorous inspection of raw materials, monitoring production

processes, and assessing finished products. Methods include visual inspections, measurements, and testing

for durability and compliance with standards. Implementing effective quality management systems, like ISO

9001, helps ensure consistency.Production methods in the garment industry vary but commonly include pattern

making, cutting, sewing, and finishing. Automation, such as computerized cutting machines, is increasingly used

for efficiency. Lean manufacturing principles, like 5S methodology, are applied to streamline processes, reduce

waste, and enhance overall productivity. Regular training and communication within the production team are vital

for maintaining high-quality standards.

Methods of Quality Control:

Piece goods quality control: On receipt of fabrics in the ware house, at least 10% are inspection as per “4 Points”

system/10 Points system/2.5 Point system/6.0 Point system. The most commonly used 4 Points system as per

below –

Penalty points for various defects:

• 3 Inches or less is equal to 1 Point

• Over 3, under 6 Inches is equal to 2 Point

• Over 6, under 9 Inches is equal to 3 Point

• Over 9 Inches is equal to 4 Point

• A maximum of 4 points are changed in one linear yard.

Quality control in Cutting section:

In cutting section quality is ensured in two stages.

a Spreading quality control: Following the point are checked during

• spreading

• Table marking.

• Ends positioning

• Tension

226

CITS : Apparel - Fashion Design & Technology - Lesson 34 - 39