Page 245 - CITS - Fitter Trade Pactical - Volume - 2

P. 245

FITTER - CITS

Mounting tools on the turret according to part & process

required

Objectives : At the end of this exercise you shall be able to

• prepare tooling sheet as per part drawing

• select suitable insert and its holder

• assemble the tool assembly in turret.

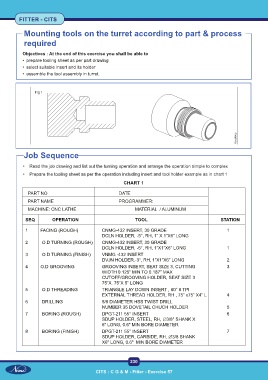

Fig 1

Job Sequence

• Read the job drawing and list out the turning operation and arrange the operation simple to complex

• Prepare the tooling sheet as per the operation including insert and tool holder example as in chart 1

CHART 1

PART NO DATE

PART NAME PROGRAMMER:

MACHINE: CNC LATHE MATERIAL / ALUMINUM

SEQ OPERATION TOOL STATION

1 FACING (ROUGH) CNMG-432 INSERT, 30 GRADE 1

DCLN HOLDER, -5°, RH, 1” X 1”X6” LONG

2 O.D TURNING (ROUGH) CNMG-432 INSERT, 30 GRADE

DCLN HOLDER, -5°, RH, 1”X1”X6” LONG 1

3 O.D TURNING (FINISH) VNMG -432 INSERT

DVJN HOLDER,-3°, RH, 1”X1”X6” LONG 2

4 O.D GROOVING GROOVING INSERT, SEAT SIZE 3, CUTTING 3

WIDTH 0.125” MIN TO 0.187” MAX

CUTOFF/GROOVING HOLDER, SEAT SIZE 3

75”X. 75”X 5” LONG

5 O.D THREADING TRIANGLE LAY DOWN INSERT , 60° 8 TPI

EXTERNAL THREAD HOLDER, RH , 75” x75” X4” L 4

6 DRILLING 5/8 DIAMETER HSS TWIST DRILL

NUMBER 35 DOVETAIL CHUCH HOLDER 5

7 BORING (ROUGH) DPGT-211 55° INSERT 6

SDUP HOLDER, STEEL, RH, ∅3/8" SHANK X

6" LONG, 0.6" MIN BORE DIAMETER

8 BORING (FINISH) DPGT-211 55° INSERT 7

SDUP HOLDER, CARBIDE, RH, ∅3/8 SHANK

X6" LONG, 0.6" MIN BORE DIAMETER

230

CITS : C G & M - Fitter - Exercise 57