Page 248 - CITS - Fitter Trade Pactical - Volume - 2

P. 248

FITTER - CITS

TASK 2 : Tool reference point and commanding point

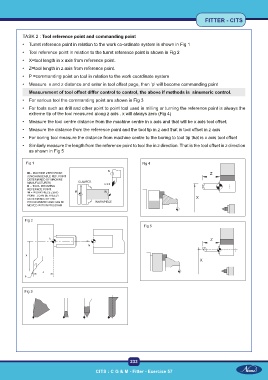

• Turret reference point in relation to the work co-ordinate system is shown in Fig 1

• Tool reference point in relation to the turret reference point is shown in Fig 2

• X=tool length in x axis from reference point.

• Z=tool length in z axis from reference point.

• P =commanding point on tool in relation to the work coordinate system

• Measure x and z distance and enter in tool offset page, then ‘p’ will become commanding point

Measurement of tool offset differ control to control, the above if methods is sinumeric control.

• For various tool the commanding point are shown in Fig 3

• For tools such as drill and other point to point tool used in milling or turning the reference point is always the

extreme tip of the tool measured along z axis . x will always zero (Fig 4)

• Measure the tool centre distance from the machine centre in x axis and that will be x axis tool offset.

• Measure the distance from the reference point and the tool tip in z and that is tool offset in z axis

• For boring tool measure the distance from machine centre to the boring to tool tip that is x axis tool offset

• Similarly measure the length from the reference point to tool the in z direction. That is the tool offset in z direction

as shown in Fig 5

Fig 1 Fig 4

Fig 2

Fig 5

Fig 3

233

CITS : C G & M - Fitter - Exercise 57 CITS : C G & M - Fitter - Exercise 57