Page 312 - CTS - Mechanic Diesel - TP

P. 312

MECHANIC DIESEL - CITS

Use a suitable adapter to clamp and connect the cleaned Common rail injector to the nozzle tester.

Use the nozzle tester to build up a pressure of > 30 MPa (300 bar) and maintain the pressure by way of constant

lever action.

Note: If pressure build-up is possible and calibrating oil only emerges at the return connection, the

component Common rail injector can be checked on the pump test bench.

If calibrating oil emerges at the nozzle, the nozzle retaining nut or in the area of the High-pressure connection

common rail injector cannot be tested but it may be possible to perform repair.

Note: On completion of repair work, the component must be checked again with the nozzle tester.

If calibrating oil emerges at the solenoid valve retaining nut, the return connection or the injector body the Common

Rail injector cannot be repaired. Replace the Common rail injector with a new one.

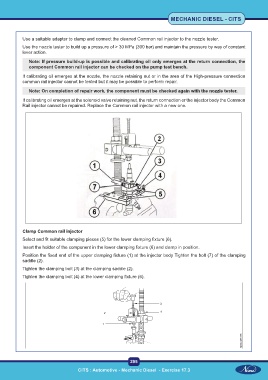

Clamp Common rail injector

Select and fit suitable clamping pieces (5) for the lower clamping fixture (6).

Insert the holder of the component in the lower clamping fixture (6) and clamp in position.

Position the fixed end of the upper clamping fixture (1) at the injector body Tighten the bolt (7) of the clamping

saddle (2).

Tighten the clamping bolt (3) at the clamping saddle (2).

Tighten the clamping bolt (4) at the lower clamping fixture (6).

295

CITS : Automotive - Mechanic Diesel - Exercise 17.3 CITS : Automotive - Mechanic Diesel - Exercise 17.3