Page 313 - CTS - Mechanic Diesel - TP

P. 313

MECHANIC DIESEL - CITS

Note: Repeat the clamping procedure if the component is not fixed vertically in position in the clamping

fixtures.

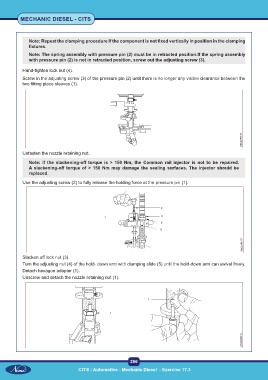

Note: The spring assembly with pressure pin (2) must be in retracted position.If the spring assembly

with pressure pin (2) is not in retracted position, screw out the adjusting screw (3).

Hand-tighten lock nut (4).

Screw in the adjusting screw (3) of the pressure pin (2) until there is no longer any visible clearance between the

two fitting piece sleeves (1).

Unfasten the nozzle retaining nut.

Note: If the slackening-off torque is > 150 Nm, the Common rail injector is not to be repaired.

A slackening-off torque of > 150 Nm may damage the sealing surfaces. The Injector should be

replaced.

Use the adjusting screw (2) to fully release the holding force at the pressure pin (1).

Slacken off lock nut (3).

Turn the adjusting nut (4) of the hold- down arm with clamping slide (5) until the hold-down arm can swivel freely.

Detach hexagon adapter (1).

Unscrew and detach the nozzle retaining nut (1).

296

CITS : Automotive - Mechanic Diesel - Exercise 17.3