Page 317 - CTS - Mechanic Diesel - TP

P. 317

MECHANIC DIESEL - CITS

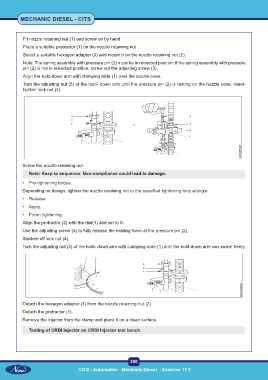

Fit nozzle retaining nut (1) and screw on by hand

Place a suitable protractor (1) on the nozzle retaining nut

Select a suitable hexagon adapter (3) and mount it on the nozzle retaining nut (2).

Note: The spring assembly with pressure pin (2) must be in retracted position.If the spring assembly with pressure

pin (2) is not in retracted position, screw out the adjusting screw (3).

Align the hold-down arm with clamping slide (1) over the nozzle cone.

Turn the adjusting nut (5) of the hold- down arm until the pressure pin (2) is resting on the nozzle cone. Hand-

tighter: lock nut (4)

Screw the nozzle retaining nut.

Note: Keep to sequence. Non-compliance could lead to damage.

• Pre-tightening torque.

Depending on design, tighten the nozzle retaining nut to the specified tightening torque/angle

• Release

• Apply.

• Finish tightening:

Align the protractor (2) with the dial(1) and set to 0◦

Use the adjusting screw (3) to fully release the holding force at the pressure pin (2).

Slacken off lock nut (4).

Turn the adjusting nut (5) of the hold- down arm with clamping slide (1) until the hold-down arm can swivel freely.

Detach the hexagon adapter (3) from the nozzle retaining nut (2)

Detach the protractor (1).

Remove the Injector from the clamp and place it on a clean surface.

Testing of CRDI Injector on CRDI Injector test bench.

300

CITS : Automotive - Mechanic Diesel - Exercise 17.3