Page 316 - CTS - Mechanic Diesel - TP

P. 316

MECHANIC DIESEL - CITS

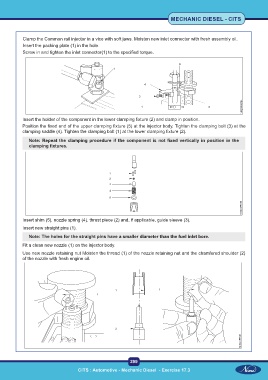

Clamp the Common rail injector in a vice with soft jaws. Moisten new inlet connector with fresh assembly oil.

Insert the packing plate (1) in the hole.

Screw in and tighten the inlet connector(1) to the specified torque.

Insert the holder of the component in the lower clamping fixture (2) and clamp in position.

Position the fixed end of the upper clamping fixture (5) at the injector body. Tighten the clamping bolt (3) at the

clamping saddle (4). Tighten the clamping bolt (1) at the lower clamping fixture (2).

Note: Repeat the clamping procedure if the component is not fixed vertically in position in the

clamping fixtures.

Insert shim (5), nozzle spring (4), thrust piece (2) and, if applicable, guide sleeve (3).

Insert new straight pins (1).

Note: The holes for the straight pins have a smaller diameter than the fuel inlet bore.

Fit a clean new nozzle (1) on the injector body.

Use new nozzle retaining nut Moisten the thread (1) of the nozzle retaining nut and the chamfered shoulder (2)

of the nozzle with fresh engine oil.

299

CITS : Automotive - Mechanic Diesel - Exercise 17.3 CITS : Automotive - Mechanic Diesel - Exercise 17.3