Page 320 - CTS - Mechanic Diesel - TP

P. 320

MECHANIC DIESEL - CITS

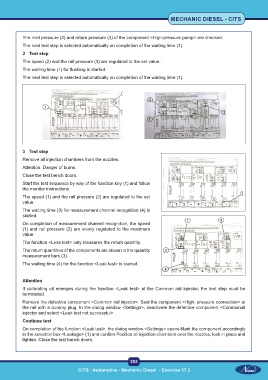

The inlet pressure (2) and return pressure (3) of the component <High-pressure pump> are checked.

The next test step is selected automatically on completion of the waiting time (1).

2 Test step

The speed (2) and the rail pressure (3) are regulated to the set value.

The waiting time (1) for flushing is started.

The next test step is selected automatically on completion of the waiting time (1).

3 Test step

Remove all injection chambers from the nozzles.

Attention: Danger of burns.

Close the test bench doors.

Start the test sequence by way of the function key (1) and follow

the monitor instructions.

The speed (1) and the rail pressure (2) are regulated to the set

value.

The waiting time (3) for measurement channel recognition (4) is

started.

On completion of measurement channel recognition, the speed

(1) and rail pressure (2) are slowly regulated to the maximum

value.

The function <Leak test> only measures the return quantity.

The return quantities of the components are shown in the quantity

measurement bars (3).

The waiting time (4) for the function <Leak test> is started.

Attention

If calibrating oil emerges during the function <Leak test> at the Common rail injector, the test step must be

terminated.

Remove the defective component <Common rail injector>. Seal the component <High- pressure connection> at

the rail with a dummy plug. In the dialog window <Settings>, deactivate the defective component <Commonail

injector and select <Leak test not successful>

Continue test

On completion of the function <Leak test>, the dialog window <Settings> opens Mark the component accordingly

in the selection box <Leakage> (1) and confirm Position all injection chambers over the nozzles, lock in place and

tighten. Close the test bench doors.

303

CITS : Automotive - Mechanic Diesel - Exercise 17.3 CITS : Automotive - Mechanic Diesel - Exercise 17.3