Page 315 - CTS - Mechanic Diesel - TP

P. 315

MECHANIC DIESEL - CITS

Clean the injector body and the components to be re-used in an ultrasonic cleaning bath.

Set the temperature of the cleaning agent to 140... 158 °F after approx. 15 min, take the component out of the

cleaning bath.

Dry all parts with compressed air.

Use a suitable tool, e.g. a suction pump, to clean the sealing surfaces at the injector body.

Inspection of the components

Check the thread for the nozzle retaining nut for contamination coke deposits corrosion and mechanical damage.

If The thread is in perfect condition. Repair is possible.

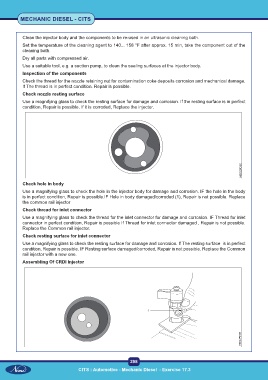

Check nozzle resting surface

Use a magnifying glass to check the resting surface for damage and corrosion. If the resting surface is in perfect

condition, Repair is possible. If it is corroded, Replace the injector.

Check hole in body

Use a magnifying glass to check the hole in the injector body for damage and corrosion. IF the hole in the body

is in perfect condition, Repair is possible.IF Hole in body damaged/corroded (1), Repair is not possible. Replace

the common rail injector

Check thread for inlet connector

Use a magnifying glass to check the thread for the inlet connector for damage and corrosion. IF Thread for inlet

connector in perfect condition, Repair is possible If Thread for inlet connector damaged , Repair is not possible.

Replace the Common rail injector.

Check resting surface for inlet connector

Use a magnifying glass to check the resting surface for damage and corrosion. If The resting surface is in perfect

condition, Repair is possible. IF Resting surface damaged/corroded, Repair is not possible. Replace the Common

rail injector with a new one.

Assembling Of CRDI Injector

298

CITS : Automotive - Mechanic Diesel - Exercise 17.3