Page 66 - CTS - Mechanic Diesel - TP

P. 66

MECHANIC DIESEL - CITS

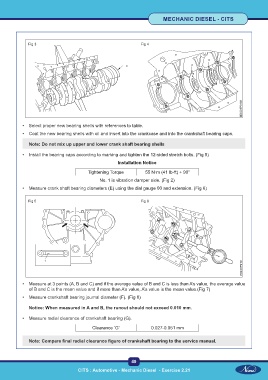

Fig 3 Fig 4

• Select proper new bearing shells with references to table.

• Coat the new bearing shells with oil and insert into the crankcase and into the crankshaft bearing caps.

Note: Do not mix up upper and lower crank shaft bearing shells

• Install the bearing caps according to marking and tighten the 12-sided stretch bolts. (Fig 5)

Installation Notice

Tightening Torque 55 N·m (41 lb-ft) + 90°

No. 1 is vibration damper side. (Fig 2)

• Measure crank shaft bearing diameters (E) using the dial gauge 00 and extension. (Fig 6)

Fig 5 Fig 6

• Measure at 3 points (A, B and C) and if the average value of B and C is less than A’s value, the average value

of B and C is the mean value and if more than A’s value, A’s value is the mean value.(Fig 7)

• Measure crankshaft bearing journal diameter (F). (Fig 8)

Notice: When measured in A and B, the runout should not exceed 0.010 mm.

• Measure radial clearance of crankshaft bearing (G).

Clearance ‘G’ 0.027-0.051 mm

Note: Compare final radial clearance figure of crankshaft bearing to the service manual.

49

CITS : Automotive - Mechanic Diesel - Exercise 2.21