Page 67 - CTS - Mechanic Diesel - TP

P. 67

MECHANIC DIESEL - CITS

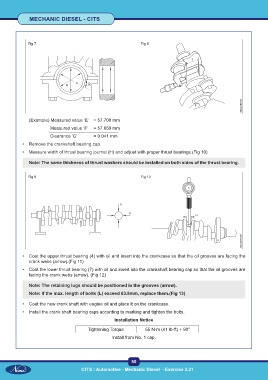

Fig 7 Fig 8

(Example) Measured value ‘E’ = 57.700 mm

Measured value ‘F’ = 57.659 mm

Clearance ‘G’ = 0.041 mm

• Remove the crankshaft bearing cap.

• Measure width of thrust bearing journal (H) and adjust with proper thrust bearings.(Fig 10)

Note: The same thickness of thrust washers should be installed on both sides of the thrust bearing.

Fig 9 Fig 10

• Coat the upper thrust bearing (4) with oil and insert into the crankcase so that the oil grooves are facing the

crank webs (arrow).(Fig 11)

• Coat the lower thrust bearing (7) with oil and insert into the crankshaft bearing cap so that the oil grooves are

facing the crank webs (arrow). (Fig 12)

Note: The retaining lugs should be positioned in the grooves (arrow).

Note: If the max. length of bolts (L) exceed 63.8mm, replace them.(Fig 13)

• Coat the new crank shaft with engine oil and place it on the crankcase.

• Install the crank shaft bearing caps according to marking and tighten the bolts.

Installation Notice

Tightening Torque 55 N·m (41 lb-ft) + 90°

Install from No. 1 cap.

50

CITS : Automotive - Mechanic Diesel - Exercise 2.21