Page 68 - CTS - Mechanic Diesel - TP

P. 68

MECHANIC DIESEL - CITS

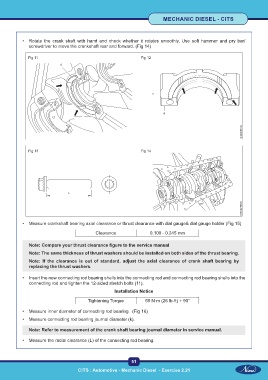

• Rotate the crank shaft with hand and check whether it rotates smoothly. Use soft hammer and pry bar/

screwdriver to move the crankshaft rear and forward. (Fig 14)

Fig 11 Fig 12

Fig 13 Fig 14

• Measure crankshaft bearing axial clearance or thrust clearance with dial gauge& dial gauge holder (Fig 15)

Clearance 0.100 - 0.245 mm

Note: Compare your thrust clearance figure to the service manual

Note: The same thickness of thrust washers should be installed on both sides of the thrust bearing.

Note: If the clearance is out of standard, adjust the axial clearance of crank shaft bearing by

replacing the thrust washers.

• Insert the new connecting rod bearing shells into the connecting rod and connecting rod bearing shells into the

connecting rod and tighten the 12-sided stretch bolts (11).

Installation Notice

Tightening Torque 55 N·m (26 lb-ft) + 90°

• Measure inner diameter of connecting rod bearing. (Fig 16)

• Measure connecting rod bearing journal diameter (k).

Note: Refer to measurement of the crank shaft bearing journal diameter in service manual.

• Measure the radial clearance (L) of the connecting rod bearing.

51

CITS : Automotive - Mechanic Diesel - Exercise 2.21 CITS : Automotive - Mechanic Diesel - Exercise 2.21