Page 179 - CTS - Sewing Technology - TP - Volume - 2-0

P. 179

SEWING TECHNOLOGY - CITS

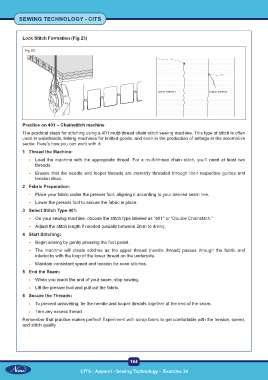

Lock Stitch Formation (Fig 23)

Fig 23

Practice on 401 – Chainstitch machine

The practical steps for stitching using a 401 multi-thread chain stitch sewing machine. This type of stitch is often

used in waistbands, linking machines for knitted goods, and even in the production of airbags in the automotive

sector. Here’s how you can work with it:

1 Thread the Machine:

- Load the machine with the appropriate thread. For a multi-thread chain stitch, you’ll need at least two

threads.

- Ensure that the needle and looper threads are correctly threaded through their respective guides and

tension discs.

2 Fabric Preparation:

- Place your fabric under the presser foot, aligning it according to your desired seam line.

- Lower the presser foot to secure the fabric in place.

3 Select Stitch Type 401:

- On your sewing machine, choose the stitch type labeled as “401” or “Double Chainstitch.”

- Adjust the stitch length if needed (usually between 2mm to 4mm).

4 Start Stitching:

- Begin sewing by gently pressing the foot pedal.

- The machine will create stitches as the upper thread (needle thread) passes through the fabric and

interlocks with the loop of the lower thread on the underside.

- Maintain consistent speed and tension for even stitches.

5 End the Seam:

- When you reach the end of your seam, stop sewing.

- Lift the presser foot and pull out the fabric.

6 Secure the Threads:

- To prevent unraveling, tie the needle and looper threads together at the end of the seam.

- Trim any excess thread.

Remember that practice makes perfect! Experiment with scrap fabric to get comfortable with the tension, speed,

and stitch quality

164

CITS : Apparel - Sewing Technology - Exercise 34