Page 139 - CITS - Welder - Trade Practical

P. 139

WELDER - CITS

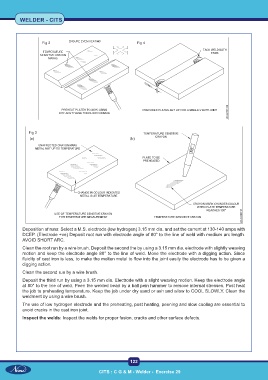

Fig 2 Fig 4

Fig 3

Deposition of runs: Select a M.S. electrode (low hydrogen) 3.15 mm dia. and set the current at 130-140 amps with

DCEP. (Electrode +ve) Deposit root run with electrode angle of 80° to the line of weld with medium arc length.

AVOID SHORT ARC.

Clean the root run by a wire brush. Deposit the second the by using a 3.15 mm dia. electrode with slightly weaving

motion and keep the electrode angle 80° to the line of weld. Move the electrode with a digging action. Since

fluidity of cast iron is less, to make the molten metal to flow into the joint easily the electrode has to be given a

digging action.

Clean the second run by a wire brush.

Deposit the third run by using a 3.15 mm dia. Electrode with a slight weaving motion. Keep the electrode angle

at 80° to the line of weld. Peen the welded bead by a ball pein hammer to remove internal stresses. Post heat

the job to preheating temperature. Keep the job under dry sand or ash and allow to COOL SLOWLY. Clean the

weldment by using a wire brush.

The use of low hydrogen electrode and the preheating, post heating, peening and slow cooling are essential to

avoid cracks in the cast iron joint.

Inspect the welds: Inspect the welds for proper fusion, cracks and other surface defects.

122

CITS : C G & M - Welder - Exercise 29