Page 144 - CITS - Welder - Trade Practical

P. 144

WELDER - CITS

Fig 1

11 Complete the joint.

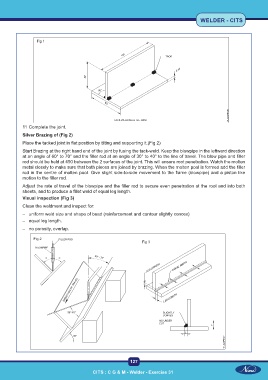

Silver Brazing of (Fig 2)

Place the tacked joint in flat position by tilting and supporting it.(Fig 2)

Start Brazing at the right hand end of the joint by fusing the tack-weld. Keep the blowpipe in the leftward direction

at an angle of 60° to 70° and the filler rod at an angle of 30° to 40° to the line of travel. The blow pipe and filler

rod should be held at 450 between the 2 surfaces of the joint. This will ensure root penetration. Watch the molten

metal closely to make sure that both pieces are joined by brazing. When the molten pool is formed add the filler

rod in the centre of molten pool. Give slight side-to-side movement to the flame (blowpipe) and a piston like

motion to the filler rod.

Adjust the rate of travel of the blowpipe and the filler rod to secure even penetration at the root and into both

sheets, and to produce a fillet weld of equal leg length.

Visual inspection (Fig 3)

Clean the weldment and inspect for:

– uniform weld size and shape of bead (reinforcement and contour slightly concex)

– equal leg length.

– no porosity, overlap.

Fig 2

Fig 3

127

CITS : C G & M - Welder - Exercise 31