Page 147 - CITS - Welder - Trade Practical

P. 147

WELDER - CITS

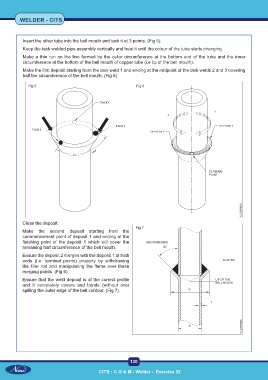

Insert the other tube into the bell mouth and tack it at 3 points. (Fig 5)

Keep the tack welded pipe assembly vertically and heat it until the colour of the tube starts changing.

Make a thin run on the line formed by the outer circumference at the bottom end of the tube and the inner

circumference at the bottom of the bell mouth of copper tube (i.e tip of the bell mouth).

Make the first deposit starting from the tack weld 1 and ending at the midpoint of the tack welds 2 and 3 covering

half the circumference of the bell mouth. (Fig 6)

Fig 5 Fig 6

Clean the deposit.

Fig 7

Make the second deposit starting from the

commencement point of deposit 1 and ending at the

finishing point of the deposit 1 which will cover the

remaining half circumference of the bell mouth.

Ensure the deposit 2 merges with the deposit 1 at both

ends (i.e. terminal points) properly by withdrawing

the filler rod and manipulating the flame over these

merging points. (Fig 6)

Ensure that the weld deposit is of the correct profile

and it completely covers and bonds (without over

spilling the outer edge of the bell contour. (Fig 7)

130

CITS : C G & M - Welder - Exercise 32 CITS : C G & M - Welder - Exercise 32