Page 148 - CITS - Welder - Trade Practical

P. 148

WELDER - CITS

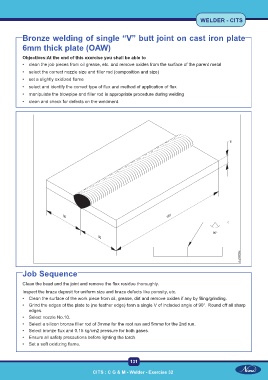

Bronze welding of single “V” butt joint on cast iron plate

6mm thick plate (OAW)

Objectives:At the end of this exercise you shall be able to

• clean the job pieces from oil grease, etc. and remove oxides from the surface of the parent metal

• select the correct nozzle size and filler rod (composition and size)

• set a slightly oxidized flame

• select and identify the correct type of flux and method of application of flux

• manipulate the blowpipe and filler rod in appropriate procedure during welding

• clean and check for defects on the weldment.

Job Sequence

Clean the bead and the joint and remove the flux residue thoroughly.

Inspect the braze deposit for uniform size and braze defects like porosity, etc.

• Clean the surface of the work piece from oil, grease, dirt and remove oxides if any by filing/grinding.

• Grind the edges of the plate to (no feather edge) form a single V of included angle of 90°. Round off all sharp

edges.

• Select nozzle No.10.

• Select a silicon bronze filler rod of 3mmø for the root run and 5mmø for the 2nd run.

• Select bronze flux and 0.15 kg/cm2 pressure for both gases.

• Ensure all safety precautions before lighting the torch.

• Set a soft oxidizing flame.

131

CITS : C G & M - Welder - Exercise 32 CITS : C G & M - Welder - Exercise 32