Page 153 - CITS - Welder - Trade Practical

P. 153

WELDER - CITS

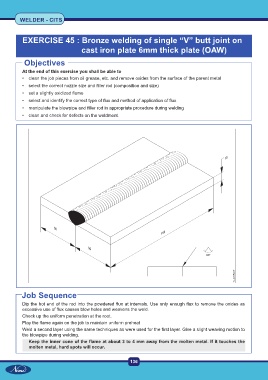

EXERCISE 45 : Bronze welding of single “V” butt joint on

cast iron plate 6mm thick plate (OAW)

Objectives

At the end of this exercise you shall be able to

• clean the job pieces from oil grease, etc. and remove oxides from the surface of the parent metal

• select the correct nozzle size and filler rod (composition and size)

• set a slightly oxidized flame

• select and identify the correct type of flux and method of application of flux

• manipulate the blowpipe and filler rod in appropriate procedure during welding

• clean and check for defects on the weldment.

Job Sequence

Dip the hot end of the rod into the powdered flux at intervals. Use only enough flux to remove the oxides as

excessive use of flux causes blow holes and weakens the weld.

Check up the uniform penetration at the root.

Play the flame again on the job to maintain uniform preheat

Weld a second layer using the same techniques as were used for the first layer. Give a slight weaving motion to

the blowpipe during welding.

Keep the inner cone of the flame at about 3 to 4 mm away from the molten metal. If it touches the

molten metal, hard spots will occur.

136

CITS : C G & M - Welder - Exercise 45