Page 158 - CITS - Welder - Trade Practical

P. 158

WELDER - CITS

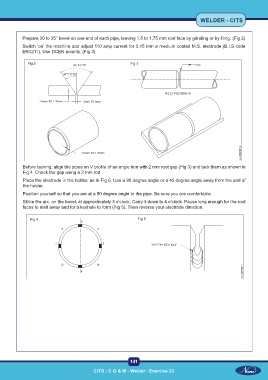

Prepare 30 to 35° bevel on one end of each pipe, leaving 1.5 to 1.75 mm root face by grinding or by filing. (Fig 2)

Switch ‘on’ the machine and adjust 110 amp current for 3.15 mm ø medium coated M.S. electrode (B.I.S code

ER4211). Use DCEN polarity. (Fig 3)

Fig 2 Fig 3

Before tacking, align the pipes on V profile of an angle iron with 2 mm root gap (Fig 3) and tack them as shown in

Fig 4. Check the gap using a 2 mm rod.

Place the electrode in the holder, as in Fig 6. Use a 90 degree angle or a 45 degree angle away from the end of

the holder.

Position yourself so that you are at a 90 degree angle to the pipe. Be sure you are comfortable.

Strike the arc, on the bevel, at approximately 3 o’clock. Carry it down to 4 o’clock. Pause long enough for the root

faces to melt away and for a keyhole to form (Fig 5). Then reverse your electrode direction.

Fig 4 Fig 5

141

CITS : C G & M - Welder - Exercise 33 CITS : C G & M - Welder - Exercise 33