Page 159 - CITS - Welder - Trade Practical

P. 159

WELDER - CITS

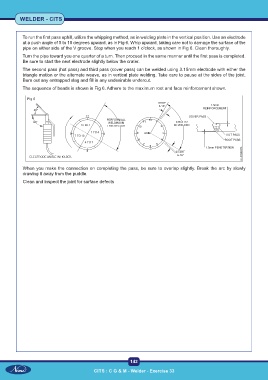

To run the first pass uphill, utilize the whipping method, as in welding plate in the vertical position. Use an electrode

at a push angle of 5 to 15 degrees upward, as in Fig 6. Whip upward, taking care not to damage the surface of the

pipe on either side of the V groove. Stop when you reach 1 o’clock, as shown in Fig 6. Clean thoroughly.

Turn the pipe toward you one quarter of a turn. Then proceed in the same manner until the first pass is completed.

Be sure to start the next electrode slightly below the crater.

The second pass (hot pass) and third pass (cover pass) can be welded using 3.15mm electrode with either the

triangle motion or the alternate weave, as in vertical plate welding. Take care to pause at the sides of the joint.

Burn out any entrapped slag and fill in any undesirable undercut.

The sequence of beads is shown in Fig 6. Adhere to the maximum root and face reinforcement shown.

Fig 6

When you make the connection on completing the pass, be sure to overlap slightly. Break the arc by slowly

drawing it away from the puddle.

Clean and inspect the joint for surface defects

142

CITS : C G & M - Welder - Exercise 33