Page 154 - CITS - Welder - Trade Practical

P. 154

WELDER - CITS

Finish the weld by filling up the crater.

Post heat the job to dull red colour

Allow the job to cool slowly by covering the job with a heap of lime or ash or dry sand.

After cooling, clean the welded job with a wire brush and inspect for weld defects like porosity, cracks,

slag inclu sions, undercut, lack of penetration etc.

• Clean the surface of the work piece from oil, grease, dirt and remove oxides if any by filing/grinding.

• Grind the edges of the plate to (no feather edge) form a single V of included angle of 90°. Round off all sharp

edges.

• Select nozzle No.10.

• Select a silicon bronze filler rod of 3mmø for the root run and 5mmø for the 2nd run.

• Select bronze flux and 0.15 kg/cm² pressure for both gases.

Skill Sequence

Bronze welding of single ‘V’ butt joint on cast iron plate of

6mm thick

Objectives: At the end of this exercise you shall be able to

• prepare and bronze welding of single ‘V’ butt joint on cast iron plate of 6mm thick.

Set the job with 30° inclinations. Keep the angle of the filler rod at 30° to 40° and give a rubbing action to the filler

rod on the V.

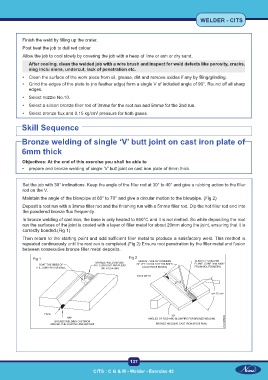

Maintain the angle of the blowpipe at 60° to 70° and give a circular motion to the blowpipe. (Fig 2)

Deposit a root run with a 3mmø filler rod and the finishing run with a 5mmø filler rod. Dip the hot filler rod end into

the powdered bronze flux frequently.

In bronze welding of cast iron, the base is only heated to 650°C and it is not melted. So while depositing the root

run the surfaces of the joint is coated with a layer of filler metal for about 20mm along the joint, ensuring that it is

correctly bonded.(Fig 1)

Then return to the starting point and add sufficient filler metal to produce a satisfactory weld. This method is

repeated continuously until the root run is completed.(Fig 2) Ensure root penetration by the filler metal and fusion

between consecutive bronze filler metal deposits.

Fig 1 Fig 2

137

CITS : C G & M - Welder - Exercise 45