Page 69 - CITS - Welder - Trade Practical

P. 69

WELDER - CITS

Job Sequence

• Mark the plate to size and cut as per drawing.

• Prepare square edges.

• Set the work piece as a ‘T’ joint.

• Select a 3.15 mm electrode and set 110 amps current.

• Connect electrode cable to-ve terminal.

• Tack-weld the work pieces at the ends. preset the plates to 2° to take care of distortion.

Note: Position the joint in vertical in the welding positioner.

• Deposit the root run with short arc length and by a slight weaving up and down motion to the electrode.

• Use whipping action for the electrode.

• Deslag and clean thoroughly with a wire brush.

Use goggles while Deslagging.

• Select a 4 mm ø electrode and set 160 amps current.

• Deposit 2nd run with short arc using a weaving motion and uniform speed of metal deposition.

• Avoid undercut.

• Ensure proper crater filling.

• Remove the welded joint from the positioner, clean and inspect for defects.

Follow the necessary safety precautions during welding.

Skill Sequence

Fillet weld ‘T’ joint on MS plate 10mm thick in vertical

position

Objectives: At the end of this exercise you shall be able to

• prepare and fillet weld ‘T’ on MS plate 10mm thick in vertical position.

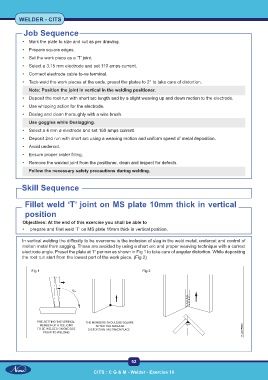

In vertical welding the difficulty to be overcome is the inclusion of slag in the weld metal, undercut and control of

molten metal from sagging. These are avoided by using a short arc and proper weaving technique with a correct

electrode angle. Preset the plate at 1° per run as shown in Fig 1 to take care of angular distortion. While depositing

the root run start from the lowest part of the work piece. (Fig 2)

Fig 1 Fig 2

52

CITS : C G & M - Welder - Exercise 10