Page 70 - CITS - Welder - Trade Practical

P. 70

WELDER - CITS

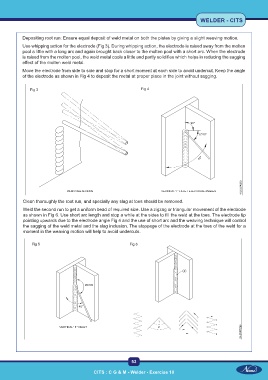

Depositing root run: Ensure equal deposit of weld metal on both the plates by giving a slight weaving motion.

Use whipping action for the electrode (Fig 3). During whipping action, the electrode is raised away from the molten

pool a little with a long arc and again brought back closer to the molten pool with a short arc. When the electrode

is raised from the molten pool, the weld metal cools a little and partly solidifies which helps in reducing the sagging

effect of the molten weld metal.

Move the electrode from side to side and stop for a short moment at each side to avoid undercut. Keep the angle

of the electrode as shown in Fig 4 to deposit the metal at proper place in the joint without sagging.

Fig 3 Fig 4

Clean thoroughly the root run, and specially any slag at toes should be removed.

Weld the second run to get a uniform bead of required size. Use a zigzag or triangular movement of the electrode

as shown in Fig 6. Use short arc length and stop a while at the sides to fill the weld at the toes. The electrode tip

pointing upwards due to the electrode angle Fig 4 and the use of short arc and the weaving technique will control

the sagging of the weld metal and the slag inclusion. The stoppage of the electrode at the toes of the weld for a

moment in the weaving motion will help to avoid undercuts.

Fig 5 Fig 6

53

CITS : C G & M - Welder - Exercise 10