Page 66 - CITS - Welder - Trade Practical

P. 66

WELDER - CITS

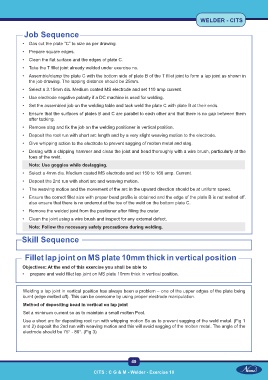

Job Sequence

• Gas cut the plate “C” to size as per drawing.

• Prepare square edges.

• Clean the flat surface and the edges of plate C.

• Take the T fillet joint already welded under exercise no.

• Assemble/clamp the plate C with the bottom side of plate B of the T fillet joint to form a lap joint as shown in

the job drawing. The lapping distance should be 25mm.

• Select a 3.15mm dia. Medium coated MS electrode and set 110 amp current.

• Use electrode negative polarity if a DC machine is used for welding.

• Set the assembled job on the welding table and tack weld the plate C with plate B at their ends.

• Ensure that the surfaces of plates B and C are parallel to each other and that there is no gap between them

after tacking.

• Remove slag and fix the job on the welding positioner in vertical position.

• Deposit the root run with short arc length and by a very slight weaving motion to the electrode.

• Give whipping action to the electrode to prevent sagging of molten metal and slag.

• Deslag with a chipping hammer and clean the joint and bead thoroughly with a wire brush, particularly at the

toes of the weld.

Note: Use goggles while deslagging.

• Select a 4mm dia. Medium coated MS electrode and set 150 to 160 amp. Current.

• Deposit the 2nd run with short arc and weaving motion.

• The weaving motion and the movement of the arc in the upward direction should be at uniform speed.

• Ensure the correct fillet size with proper bead profile is obtained and the edge of the plate B is not melted off.

also ensure that there is no undercut at the toe of the weld on the bottom plate C.

• Remove the welded joint from the positioner after filling the crater.

• Clean the joint using a wire brush and inspect for any external defect.

Note: Follow the necessary safety precautions during welding.

Skill Sequence

Fillet lap joint on MS plate 10mm thick in vertical position

Objectives: At the end of this exercise you shall be able to

• prepare and weld fillet lap joint on MS plate 10mm thick in vertical position.

Welding a lap joint in vertical position has always been a problem – one of the upper edges of the plate being

burnt (edge melted off). This can be overcome by using proper electrode manipulation.

Method of depositing bead in vertical on lap joint

Set a minimum current so as to maintain a small molten Pool.

Use a short arc for depositing root run with whipping motion So as to prevent sagging of the weld metal. (Fig 1

and 2) deposit the 2nd run with weaving motion and this will avoid sagging of the molten metal. The angle of the

electrode should be 75° - 80°. (Fig 3)

49

CITS : C G & M - Welder - Exercise 10