Page 63 - CITS - Welder - Trade Practical

P. 63

WELDER - CITS

• Deposit 2nd and final 3rd run to complete the joint in horizontal position.

• Deslag each run and clean the bead.

• Inspect the welded joint for defects.

Skill Sequence

Single ‘V’ butt joint on MS plate 12mm thick in horizontal

position

Objectives: At the end of this exercise you shall be able to

• prepare and weld single V butt joint on MS plate 12mm thick in horizontal position.

Prepare the beveling by gas cutting and filling.

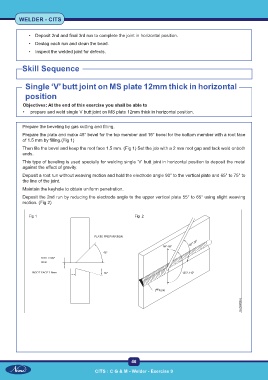

Prepare the plate and make 45° bevel for the top member and 15° bevel for the bottom member with a root face

of 1.5 mm by filling.(Fig 1)

Then file the bevel and keep the root face 1.5 mm. (Fig 1) Set the job with a 2 mm root gap and tack weld onboth

ends.

This type of beveling is used specially for welding single ‘V’ butt joint in horizontal position to deposit the metal

against the effect of gravity.

Deposit a root run without weaving motion and hold the electrode angle 90° to the vertical plate and 65° to 75° to

the line of the joint.

Maintain the keyhole to obtain uniform penetration.

Deposit the 2nd run by reducing the electrode angle to the upper vertical plate 55° to 65° using slight weaving

motion. (Fig 2)

Fig 1 Fig 2

46

CITS : C G & M - Welder - Exercise 9