Page 61 - CITS - Welder - Trade Practical

P. 61

WELDER - CITS

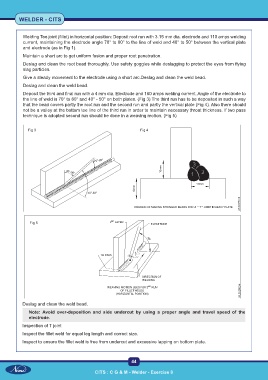

Welding Tee joint (fillet) in horizontal position: Deposit root run with 3.15 mm dia. electrode and 110 amps welding

current, maintaining the electrode angle 70° to 80° to the line of weld and 40° to 50° between the vertical plate

and electrode (as in Fig 1).

Maintain a short arc to get uniform fusion and proper root penetration.

Deslag and clean the root bead thoroughly. Use safety goggles while deslagging to protect the eyes from flying

slag particles.

Give a steady movement to the electrode using a short arc.Deslag and clean the weld bead.

Deslag and clean the weld bead.

Deposit the third and final run with a 4 mm dia. Electrode and 160 amps welding current. Angle of the electrode to

the line of weld is 70° to 80° and 40° - 50° on both plates. (Fig 3) The third run has to be deposited in such a way

that the bead covers partly the root run and the second run and partly the vertical plate (Fig 4). Also there should

not be a valley at the bottom toe line of the third run in order to maintain necessary throat thickness. If two pass

technique is adopted second run should be done in a weaving motion. (Fig 5)

Fig 3 Fig 4

Fig 5

Deslag and clean the weld bead.

Note: Avoid over-deposition and side undercut by using a proper angle and travel speed of the

electrode.

Inspection of T joint

Inspect the fillet weld for equal leg length and correct size.

Inspect to ensure the fillet weld is free from undercut and excessive lapping on bottom plate.

44

CITS : C G & M - Welder - Exercise 8