Page 117 - CITS - Welder - Trade Theory

P. 117

WELDER - CITS

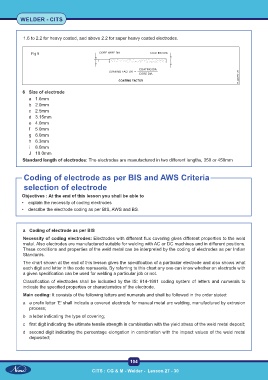

1.6 to 2.2 for heavy coated, and above 2.2 for super heavy coated electrodes.

Fig 6

6 Size of electrode

a 1.6mm

b 2.0mm

c 2.5mm

d 3.15mm

e 4.0mm

f 5.0mm

g 6.0mm

h 6.3mm

i 8.0mm

J 10.0mm

Standard length of electrodes: The electrodes are manufactured in two different lengths, 350 or 450mm

Coding of electrode as per BIS and AWS Criteria

selection of electrode

Objectives : At the end of this lesson you shall be able to

• explain the necessity of coding electrodes

• describe the electrode coding as per BIS, AWS and BS.

a Coding of electrode as per BIS

Necessity of coding electrodes: Electrodes with different flux covering gives different properties to the weld

metal. Also electrodes are manufactured suitable for welding with AC or DC machines and in different positions.

These conditions and properties of the weld metal can be interpreted by the coding of electrodes as per Indian

Standards.

The chart shown at the end of this lesson gives the specification of a particular electrode and also shows what

each digit and letter in the code represents. By referring to this chart any one can know whether an electrode with

a given specification can be used for welding a particular job or not.

Classification of electrodes shall be indicated by the IS: 814-1991 coding system of letters and numerals to

indicate the specified properties or characteristics of the electrode.

Main coding: It consists of the following letters and numerals and shall be followed in the order stated:

a a prefix letter ‘E’ shall indicate a covered electrode for manual metal arc welding, manufactured by extrusion

process;

b a letter indicating the type of covering;

c first digit indicating the ultimate tensile strength in combination with the yield stress of the weld metal deposit;

d second digit indicating the percentage elongation in combination with the impact values of the weld metal

deposited;

104

CITS : CG & M - Welder - Lesson 27 - 30