Page 162 - CITS - Welder - Trade Theory

P. 162

WELDER - CITS

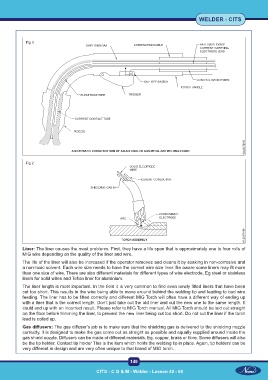

Fig 1

Fig 2

Liner: The liner causes the most problems. First, they have a life span that is approximately one to four rolls of

MIG wire depending on the quality of the liner and wire.

The life of the liner will also be increased if the operator removes and cleans it by soaking in non-corrosive and

a non-toxic solvent. Each wire size needs to have the correct wire size liner. Be aware some liners may fit more

than one size of wire. There are also different materials for different types of wire electrode, Eg steel or stainless

liners for solid wires and Teflon liner for aluminium.

The liner length is most important. In the field it is very common to find even newly fitted liners that have been

cut too short. This results in the wire being able to move around behind the welding tip and leading to bad wire

feeding. The liner has to be fitted correctly and different MIG Torch will often have a different way of ending up

with a liner that is the correct length. Don’t just take out the old liner and cut the new one to the same length. It

could end up with an incorrect result. Please refer to MIG Torch manual. All MIG Torch should be laid out straight

on the floor before trimming the liner, to prevent the new liner being cut too short. Do not cut the liner if the torch

lead is coiled up.

Gas diffusers: The gas diffuser’s job is to make sure that the shielding gas is delivered to the shielding nozzle

correctly. It is designed to make the gas come out as straight as possible and equally supplied around inside the

gas shield nozzle. Diffusers can be made of different materials, Eg. copper, brass or fibre. Some diffusers will also

be the tip holder. Contact tip holder This is the item which holds the welding tip in place. Again, tip holders can be

very different in design and are very often unique to that brand of MIG torch.

149

CITS : C G & M - Welder - Lesson 49 - 60