Page 257 - CITS - Welder - Trade Theory

P. 257

WELDER - CITS

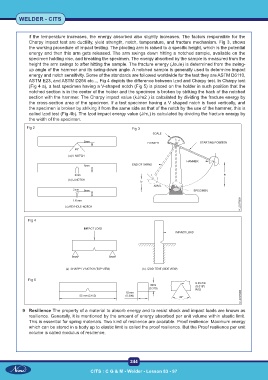

if the temperature increases, the energy absorbed also slightly increases. The factors responsible for the

Charpy impact test are ductility, yield strength, notch, temperature, and fracture mechanism. Fig 3, shows

the working procedure of impact testing. The pivoting arm is raised to a specific height, which is the potential

energy and then this arm gets released. The arm swings down hitting a notched sample, available on the

specimen holding vise, and breaking the specimen. The energy absorbed by the sample is measured from the

height the arm swings to after hitting the sample. The fracture energy (Joule) is determined from the swing-

up angle of the hammer and its swing-down angle. A notched sample is generally used to determine impact

energy and notch sensitivity. Some of the standards are followed worldwide for the test they are ASTM D6110,

ASTM E23, and ASTM D256 etc..., Fig 4 depicts the difference between Izod and Charpy test. In Charpy test

(Fig 4 a), a test specimen having a V-shaped notch (Fig 5) is placed on the holder in such position that the

notched section is in the center of the holder and the specimen is broken by striking the back of the notched

section with the hammer. The Charpy impact value (kJ/m2 ) is calculated by dividing the fracture energy by

the cross-section area of the specimen. If a test specimen having a V shaped notch is fixed vertically, and

the specimen is broken by striking it from the same side as that of the notch by the use of the hammer, this is

called Izod test (Fig 4b). The Izod impact energy value (J/m,) is calculated by dividing the fracture energy by

the width of the specimen.

Fig 2 Fig 3

Fig 4

Fig 5

9 Resilience The property of a material to absorb energy and to resist shock and impact loads are known as

resilience. Generally, it is mentioned by the amount of energy absorbed per unit volume within elastic limit.

This is essential for spring materials. Two kind of resilience are available. Proof resilience: Maximum energy

which can be stored in a body up to elastic limit is called the proof resilience. But the Proof resilience per unit

volume is called modulus of resilience.

244

CITS : C G & M - Welder - Lesson 83 - 97