Page 258 - CITS - Welder - Trade Theory

P. 258

WELDER - CITS

Impact test:

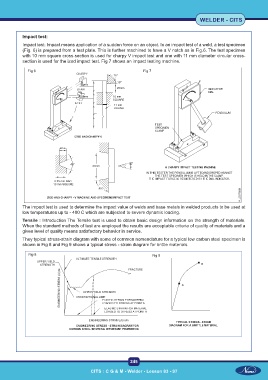

Impact test: Impact means application of a sudden force on an object. In an impact test of a weld, a test specimen

(Fig. 6) is prepared from a test plate. This is further machined to have a V notch as in Fig.6. The test specimen

with 10 mm square cross-section is used for charpy V impact test and one with 11 mm diameter circular cross-

section is used for the izod impact test. Fig 7 shows an impact testing machine.

Fig 6 Fig 7

The impact test is used to determine the impact value of welds and base metals in welded products to be used at

low temperatures up to - 400 C which are subjected to severe dynamic loading.

Tensile : Introduction The Tensile test is used to obtain basic design information on the strength of materials.

When the standard methods of test are employed the results are acceptable criteria of quality of materials and a

given level of quality means satisfactory behavior in service.

They typical stress-strain diagram with some of common nomenclature for a typical low carbon steel specimen is

shown in Fig 8 and Fig 9 shows a typical stress - strain diagram for brittle materials

Fig 8 Fig 9

245

CITS : C G & M - Welder - Lesson 83 - 97