Page 208 - CTS - Dress Making - TP - Volume - 1

P. 208

DRESS MAKING - CITS

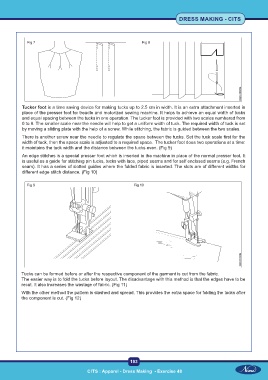

Fig 7 Fig 8

Tucker foot is a time saving device for making tucks up to 2.5 cm in width. It is an extra attachment inserted in

place of the presser foot for treadle and motorized sewing machine. It helps to achieve an equal width of tucks

and equal spacing between the tucks in one operation. The tucker foot is provided with two scales numbered from

0 to 8. The smaller scale near the needle will help to get a uniform width of tuck. The required width of tuck is set

by moving a sliding plate with the help of a screw. While stitching, the fabric is guided between the two scales.

There is another screw near the needle to regulate the space between the tucks. Set the tuck scale first for the

width of tuck, then the space scale is adjusted to a required space. The tucker foot does two operations at a time:

it maintains the tuck width and the distance between the tucks even. (Fig 9)

An edge stitches is a special presser foot which is inserted in the machine in place of the normal presser foot. It

is useful as a guide for stitching pin tucks, tucks with lace, piped seams and for self enclosed seams (e.g. French

seam). It has a series of slotted guides where the folded fabric is inserted. The slots are of different widths for

different edge stitch distance. (Fig 10)

Fig 9 Fig 10

Tucks can be formed before or after the respective component of the garment is cut from the fabric.

The easier way is to fold the tucks before layout. The disadvantage with this method is that the edges have to be

recut. It also increases the wastage of fabric. (Fig 11)

With the other method the pattern is slashed and spread. This provides the extra space for folding the tucks after

the component is cut. (Fig 12)

193

CITS : Apparel - Dress Making - Exercise 48