Page 230 - CITS - Fitter Trade Pactical - Volume - 2

P. 230

FITTER - CITS

Inspection of bevel cut: Clean the slag if sticking to the cut surface by a chipping hammer and wire brush and

inspect for any gas cutting defects.

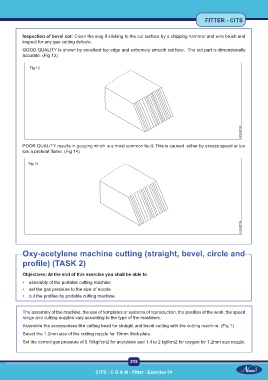

GOOD QUALITY is shown by excellent top edge and extremely smooth cut face. The cut part is dimensionally

accurate. (Fig 13)

Fig 13

POOR QUALITY results in gouging which is a most common fault. This is caused either by excess speed or too

low a preheat flame. (Fig 14)

Fig 14

Oxy-acetylene machine cutting (straight, bevel, circle and

profile) (TASK 2)

Objectives: At the end of this exercise you shall be able to

• assembly of the portable cutting machine

• set the gas pressure to the size of nozzle

• cut the profiles by portable cutting machine.

The assembly of the machine, the use of templates or systems of reproduction, the position of the work, the speed

range and cutting nozzles vary according to the type of the machines.

Assemble the accessorises like cutting head for straight and bevel cutting with the cutting machine. (Fig 1)

Select the 1.2mm size of the cutting nozzle for 10mm thick plate.

Set the correct gas pressure of 0.15kgf/cm2 for acetylene and 1.4 to 2 kgf/cm2 for oxygen for 1.2mm size nozzle.

215

CITS : C G & M - Fitter - Exercise 54