Page 227 - CITS - Fitter Trade Pactical - Volume - 2

P. 227

FITTER - CITS

Fig 4

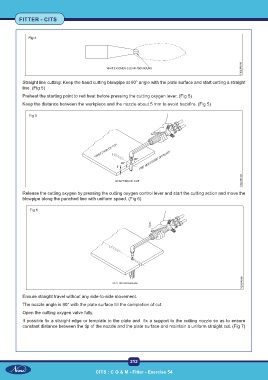

Straight line cutting: Keep the hand cutting blowpipe at 90° angle with the plate surface and start cutting a straight

line. (Fig 5)

Preheat the starting point to red heat before pressing the cutting oxygen lever. (Fig 5)

Keep the distance between the workpiece and the nozzle about 5 mm to avoid backfire. (Fig 5)

Fig 5

Release the cutting oxygen by pressing the cutting oxygen control lever and start the cutting action and move the

blowpipe along the punched line with uniform speed. (Fig 6)

Fig 6

Ensure straight travel without any side-to-side movement.

The nozzle angle is 90° with the plate surface till the completion of cut.

Open the cutting oxygen valve fully.

If possible fix a straight edge or template to the plate and fix a support to the cutting nozzle so as to ensure

constant distance between the tip of the nozzle and the plate surface and maintain a uniform straight cut. (Fig 7)

212

CITS : C G & M - Fitter - Exercise 54