Page 225 - CITS - Fitter Trade Pactical - Volume - 2

P. 225

FITTER - CITS

Skill Sequence

Oxy-acetylene hand cutting straight and bevel cut

(TASK 1)

Objectives: At the end of this exercise you shall be able to

• set the gas cutting plant

• set the job for cutting

• adjust the cutting flame for gas cutting.

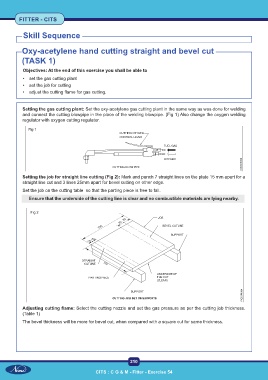

Setting the gas cutting plant: Set the oxy-acetylene gas cutting plant in the same way as was done for welding

and connect the cutting blowpipe in the place of the welding blowpipe. (Fig 1) Also change the oxygen welding

regulator with oxygen cutting regulator.

Fig 1

Setting the job for straight line cutting (Fig 2): Mark and punch 7 straight lines on the plate 15 mm apart for a

straight line cut and 3 lines 25mm apart for bevel cutting on other edge.

Set the job on the cutting table so that the parting piece is free to fall.

Ensure that the underside of the cutting line is clear and no combustible materials are lying nearby.

Fig 2

Adjusting cutting flame: Select the cutting nozzle and set the gas pressure as per the cutting job thickness.

(Table 1)

The bevel thickness will be more for bevel cut, when compared with a square cut for same thickness.

210

CITS : C G & M - Fitter - Exercise 54