Page 223 - CITS - Fitter Trade Pactical - Volume - 2

P. 223

FITTER - CITS

Job Sequence

TASK 1 : Oxy - acetylene hand cutting straight and bevel cut

• Wear all safety clothing.

• Set the gas welding plant with a cutting blowpipe, and cutting oxygen regulator.

• Fit the correct cutting nozzle according to the thickness of the metal to be cut (for M.S. plate 10mm thickness

use 1.2mm dia. orifice cutting nozzle)

• Adjust both oxygen and acetylene gas pressure according to the cutting nozzle size. (Oxygen 1.6 kgf/sq.cm

and acetylene 0.15 kgf/sq.cm)

While adjusting the pressure keep the cutting blow pipe walls open

• Check the size of the raw material

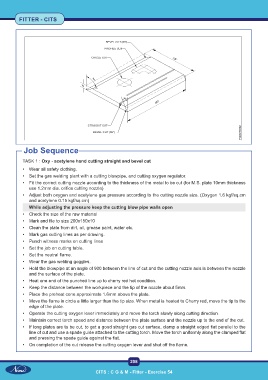

• Mark and file to size 200x150x10

• Clean the plate from dirt, oil, grease paint, water etc.

• Mark gas cutting lines as per drawing.

• Punch witness marks on cutting lines

• Set the job on cutting table.

• Set the neutral flame.

• Wear the gas welding goggles.

• Hold the blowpipe at an angle of 900 between the line of cut and the cutting nozzle axis is between the nozzle

and the surface of the plate.

• Heat one end of the punched line up to cherry red hot condition.

• Keep the distance between the workpiece and the tip of the nozzle about 5mm.

• Place the preheat cone approximate 1.6mm above the plate.

• Move the flame in circle a little larger than the tip size. When metal is heated to Cherry red, move the tip to the

edge of the plate.

• Operate the cutting oxygen lever immediately and move the torch slowly along cutting direction.

• Maintain correct torch speed and distance between the plate surface and the nozzle up to the end of the cut.

• If long plates are to be cut, to get a good straight gas cut surface, clamp a straight edged flat parallel to the

line of cut and use a spade guide attached to the cutting torch. Move the torch uniformly along the clamped flat

and pressing the spade guide against the flat.

• On completion of the cut release the cutting oxygen lever and shut off the flame.

208

CITS : C G & M - Fitter - Exercise 54