Page 169 - CTS - Mechanic Diesel - TP

P. 169

MECHANIC DIESEL - CITS

Inspection and Repair

Checking of commutator

Inspect the surface of the commuter should be clean and free from grooves, pits or uneven dipo colouration.

Clean the commutator surface by emery sheet A Coarse cut should first be mate to remove sufficient copper to

clear traces of pitting or distortion. Undercut the commutator, that is the insulation should be removed to a depth

not exceeding the width of the insulation. Finally, the component should again be set up on the lathe and a fine

finishing cut taken using a diamond or tungsten carbide tripped tool to obtain the desired quality of finish. After

matching the commutator, armature must be cleaned thoroughly preferably by means of compressed air, or by

the use of hand bellows

The minimum dia.to which the commutator can be skimmed and still remain serviceable is 45.6 mm (original dia

48 + 0.15 mm)

Checking of Armature winding

Use a 2.3v AC mains and a 220 15w bulb with two probes one of which is applied to the armature core and the

other to all the segment of the commutator in turn. In the vent of the armature being found to be faulty, it must be

replaced.

Press the cultch outer race on the shaft of the new or replacement armature,

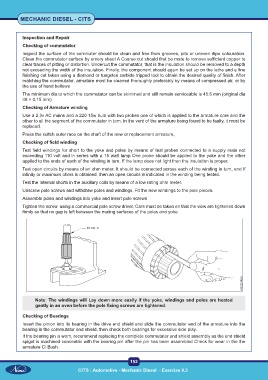

Checking of field winding

Test field windings for short to the yoke and poles by means of test probes connected to a supply main not

exceeding 110 volt and in series with a 15 watt lamp One probe should be applied to the yoke and the other

applied to the ends of each of the winding in turn. If the lamp does not light then the insulation is proper.

Test open circuits by means of an ohm meter. It should be connected across each of the winding in turn, and if

infinity or maximum ohms is obtained, then an open circuits is indicated in the winding being tested.

Test the Internal shorts in the auxiliary coils by means of a low rating ohm meter.

Unscrew pole screws and withdraw poles and windings, Fit the new windings to the pole pieces.

Assemble poles and windings into yoke and insert pole screws

Tighten the screw using a commercial pole screw driver, Care must be taken en that the view are tightened down

firmly so that no gap is left between the mating surfaces of the poles and yoke

Note: The windings will Lay down more easily if the yoke, windings and poles are heated

gently in an oven before the pole fixing screws are tightened.

Checking of Bearings

Insert the pinion into its bearing in the drive end shield and slide the commutator end of the armature into the

bearing in the commutator end shield, then check both bearings for excessive side play.

If the bearing pin is worn, recommend replacing the complete commutator end shield assembly as the end shield

spigot is machined concentric with the bearing pin after the pin has been assembled Check for wear in the the

armature CI Bush.

152

CITS : Automotive - Mechanic Diesel - Exercise 9.3