Page 170 - CTS - Mechanic Diesel - TP

P. 170

MECHANIC DIESEL - CITS

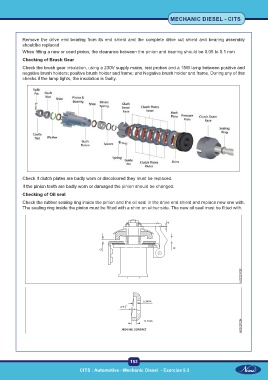

Remove the drive end bearing from its end shield and the complete drive cut shield and bearing assembly

shouldbe replaced

When fitting a new or used pinion, the clearance between the pinion and bearing should be 0.05 to 0.1 mm

Checking of Brush Gear

Check the brush gear insulation, using a 230V supply mains, test probes and a 15W lamp between positive and

negative brush holders; positive brush holder and frame; and Negative brush holder and frame, During any of this

checks if the lamp lights, the insolation is faulty.

Check If clutch plates are badly worn or discoloured they must be replaced.

If the pinion teeth are badly worn or damaged the pinion should be changed.

Checking of Oil seal

Check the rubber sealing ring inside the pinion and the oil seal in the drive end shield and replace new one with.

The sealing ring inside the pinion must be fitted with a shim on either side. The new oil seal must be fitted with.

153

CITS : Automotive - Mechanic Diesel - Exercise 9.3