Page 171 - CTS - Mechanic Diesel - TP

P. 171

MECHANIC DIESEL - CITS

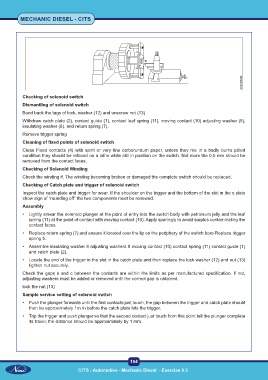

Checking of solenoid switch

Dismantling of solenoid switch

Bend back the tags of lock, washer (12) and unscrew nut (13)

Withdraw catch plate (2), contact guide (1), contact leaf spring (11), moving contact (10) adjusting washer (9),

insulating washer (8), and return spring (7).

Remove trigger spring

Cleaning of fixed points of solenoid switch

Clean Fixed contacts (4) with spirit or very fine carborundum paper, unless they me in a badly burns pitted

condition they should be refaced on a lathe while still in position on the switch. Not more the 0.5 mm should be

removed from the contact faces.

Checking of Solenoid Winding

Check the winding if. The winding becoming broken or damaged the complete switch should be replaced.

Checking of Catch plate and trigger of solenoid switch

Inspect the catch plate and trigger for wear. If the shoulder on the trigger and the bottom of the slot in the s plate

show sign of “rounding off” the two components must be renewed.

Assembly

• Lightly smear the solenoid plunger at the point of entry into the switch body with petroleum jelly and the leaf

spring (11) at the point of contact with moving contact (10). Apply sparingly to avoid surplus contaminating the

contact faces.

• Replace return spring (7) and ensure it located over the lip on the periphery of the switch bore Replace trigger

spring 5.

• Assemble insulating washer 8 adjusting washers 9 moving contact (10) contact spring (11) contact guide (1)

and catch plate (2).

• Locate the end of the trigger in the slot in the catch plate and then replace the lock washer (12) and nut (13)

tighten nut securely.

Check the gaps b and c between the contacts are within the limits as per manufactured specification. If not,

adjusting washers must be added or removed until the correct gap is obtained.

lock the nut (13)

Sample service setting of solenoid switch

• Push the plunger forwards until the first contacts just touch, the gap between the trigger and catch plate should

then be approximately 1m m before the catch plate hits the trigger.

• Trip the trigger and push plunger so that the second contact just touch from this point tell the plunger complete

its travel, the distance should be approximately by 1 mm.

154

CITS : Automotive - Mechanic Diesel - Exercise 9.3